What is important when you design heat pump heating system?

When you put in Google words Heat pump, you will find 269 000 000 results. Everyone in Europe today is talking about heat pumps, from colder countries on the north to hotter countries on the south. This topic is even more popular since the war in Ukraine started more than one year ago and everyone is trying to escape from natural gas.

But what is really heat pump, or more important question, how to actually design system to achieve high efficiency and high comfort level? The basic principle is core of the all heating systems:

- What does the building need (what is it’s power requirement at outside design temp)?

- What power can the home provide (emitters – underfloor heating, radiators etc.)?

Here will be explained 3 most important things: building’s thermal losses, capacity and system volume.

- THERMAL LOSSES AND EFFICIENCY

First important thing is to calculate the thermal losses of a building, which vary depending on the outdoor temperature (TO). Let’s take an example with new 200 m2 house with good insulation and windows as an example:

- At TO of -10°C and indoor temperature (TR) of +20 °C (dT = 30 °C), such a house requires 9 kW of heat (45 W/m2).

- At TO of +10°C and TR of +20°C (dT=10 °C), such a house requires only 3 kW of heat (15 W/m2), which is 1/3 of design heat load!

Actually, at which percentage is lower difference between TR and TO, the same percentage lower is the power needed.

How to efficiently start up the system?

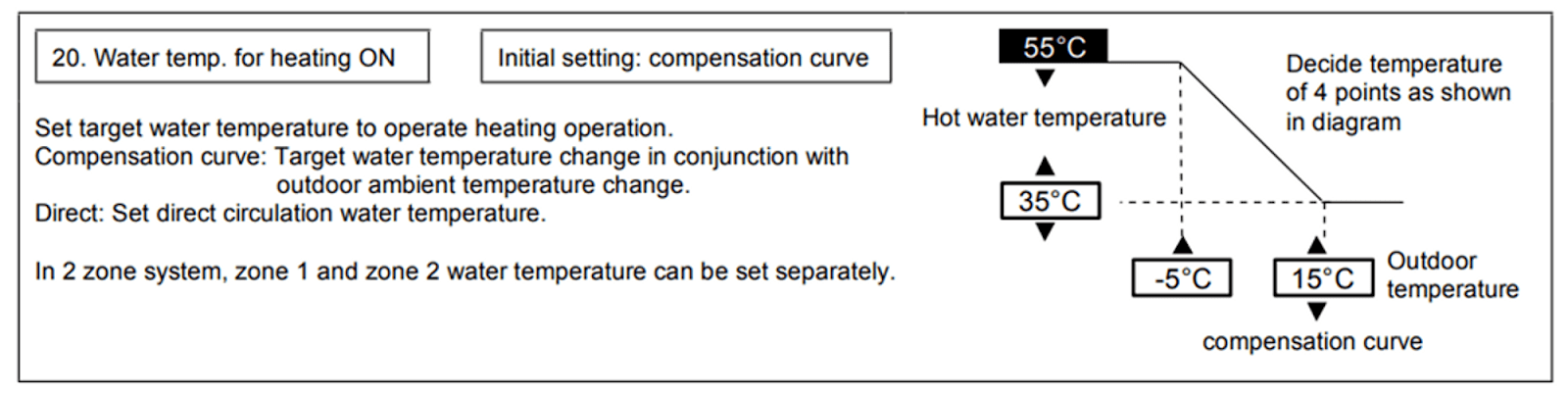

- When starting up, choose the compensation curve – the LWT is higher at lower outdoor temperatures (e.g., +40 °C at TO of -10 °C) and lower at higher outdoor temperatures (e.g., +30 °C at TO of +10 °C). In that case, the device will modulate and track the building’s heat losses. Heating delivery from emitters will be constant without constantly ON and OFF —> efficiency and comfort will be high

Figure 1. Panasonic compensation curve

- If a fixed LWT is chosen, the device will always deliver the designed capacity at fast speed, which is unnecessary at higher TO and it will go ON and OFF frequently —> increased costs and low comfort level

- CAPACITY AND FLOW RATE

When we know capacity, we need to design the system. It is important to remember that the nominal capacity Q depends on the nominal flow rate m at the nominal temperature difference between the flow and return water dT of 5 K (e.g. 35/30 °C temperature regime).

The thermodynamic capacity (heat) formula is:

Q = m x c x dT [kW]

where

- m is the symbol for mass, in this case water volumetric flow rate (L/sec)

- c is the specific heat capacity of water, a constant of 4.2 kJ/kgK

- dT is the temperature difference between the supply and return water, optimally 5 K

From the above formula, the flow rate can always be calculated at a given capacity.

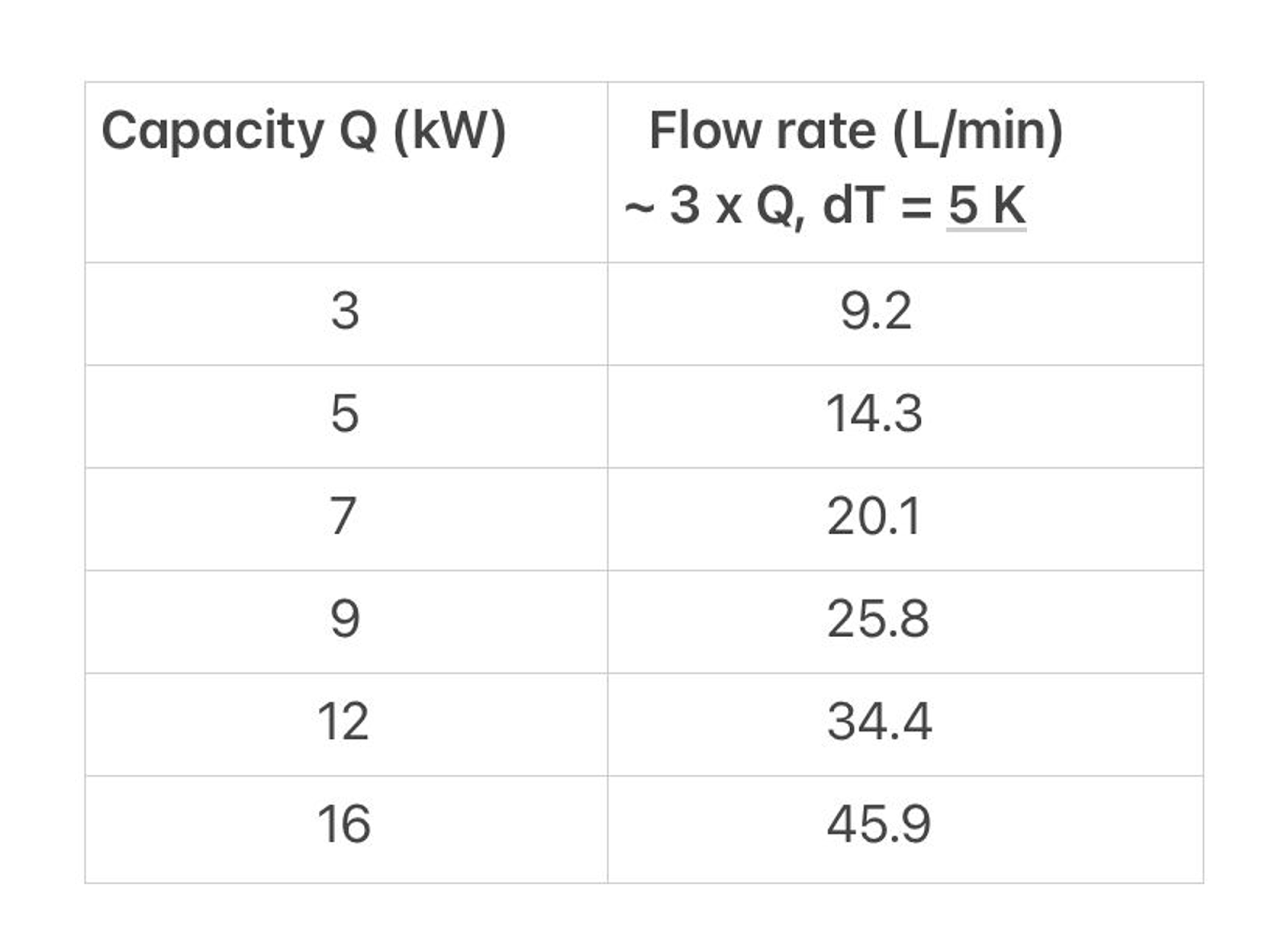

For example, a 9 kW heat pump has a nominal flow rate of 25.8 L/min:

m = 9 / (4.2 x 5) = 0.43 L/sec —> multiplied by 60 to get L/min —> 25.8 L/min

This is the optimal case in which the nominal capacity will be achieved.

If the flow rate is 50% lower, 12.9 L/min, dT must be twice as large (10 K) to achieve 9 kW of heat, which means lower comfort level and longer compressor operation to achieve capacity.

When there is an bigger delta T, then the hysteresis to switch ON the compressor is bigger as well. This means, the compressor starts later. If the compressor starts later, then unit is working longer on lower water flow temperatures. This will results in an higher COP during an ON/OFF cycle.

Quick formula to approximately calculate flow rate in L/min at a given capacity for dT = 5 K:

m = Q x 60 / 21 ~ 3 x Q [L/min]

Figure 2. Example of Panasonic heat pump models – capacity and flow rate

- BUFFER AND SYSTEM VOLUME

The correct amount of water (volume) in a heat pump heating system is crucial for proper system operation. When we talk about the volume of the system, it is important to distinguish between the TOTAL volume and the MINIMUM volume in the system. It is necessary to ensure sufficient volume in the worst-case scenario, when all circuits (underfloor heating) or valves (radiators, fan coils) are closed. In this case, the minimum volume must be sufficient for:

- DEFROST – defrosting the outdoor unit in high humidity, minimum 30-50 L of water, depending on power

- MINIMUM FLOW RATE – for the unit to work without errors at minimum capacity

- COMPRESSOR MODULATION – lower consumption and longer service life if there are no frequent ON/OFF cycles

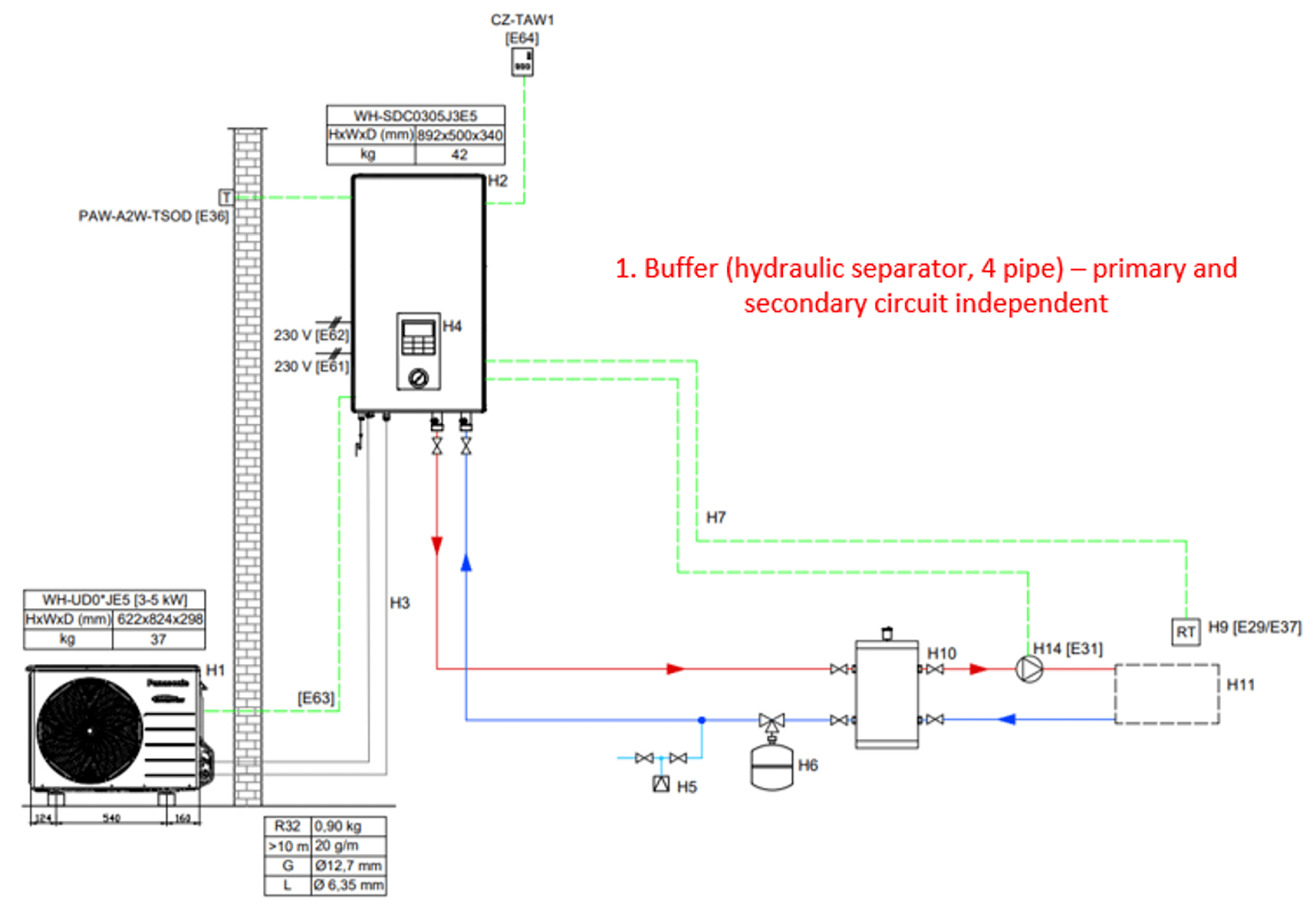

The simplest solution is to design the system with a buffer (4 pipes, like a hydraulic separator, Figure 3) and separate the hydraulic primary circuit (heat pump) from the secondary circuit (consumers). The approximate calculation is 10 L/kW nominal power:

Figure 3. Panasonic heat pump system with buffer like a hydraulic separator

However, systems with a buffer have some disadvantages:

- More expensive investment – buffer, valves, secondary pump, installation space

- Lower COP – the unit runs 24/7, even when it is not needed if the demand on the consumer side is satisfied

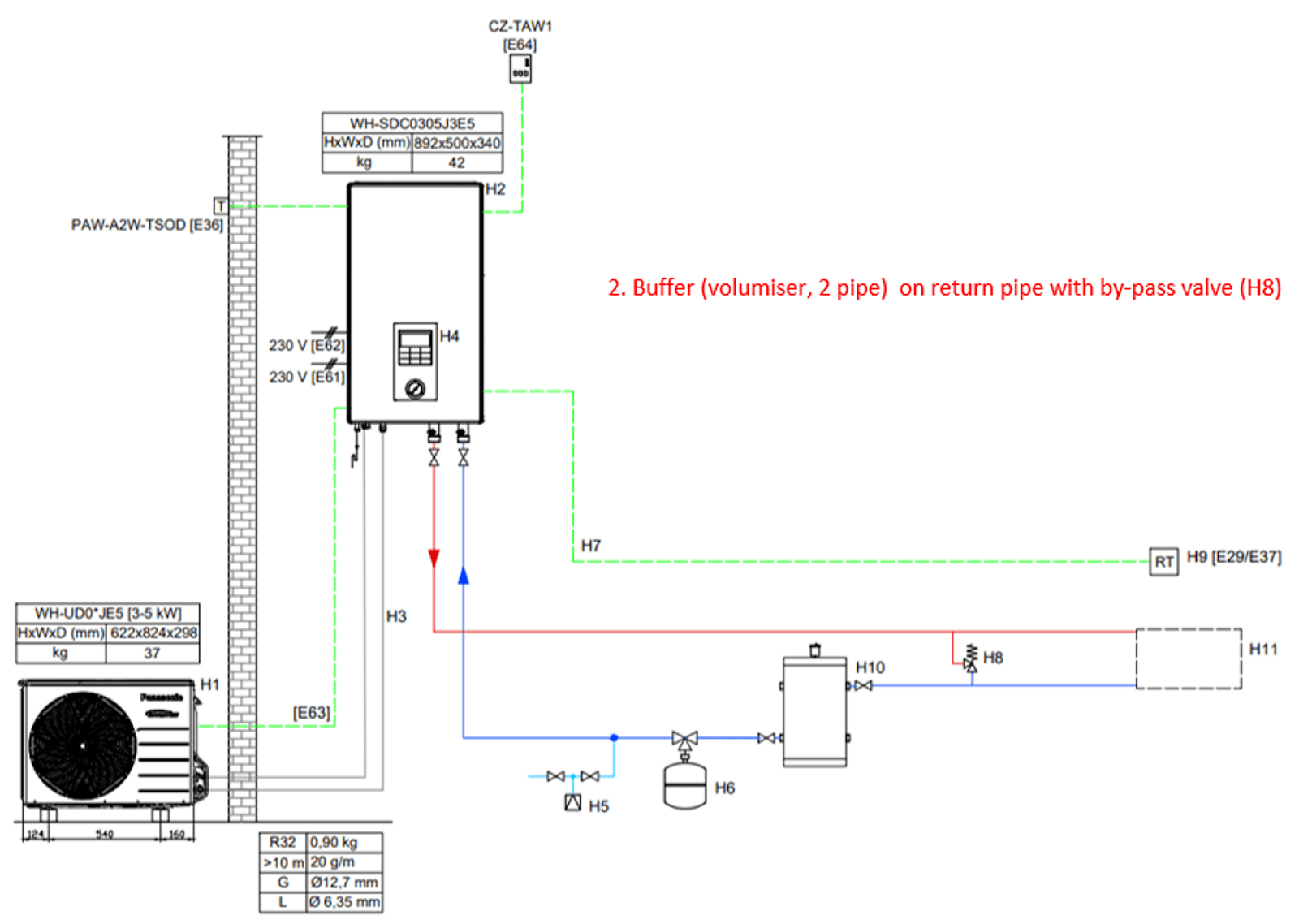

With proper sizing and hydraulic balancing, a classic buffer is not needed, but in that case, it is ideal to install a smaller “volumiser” (2 pipes, Figure 4) on the return pipe as an increase in volume in case of defrost and lower load:

Figure 4. Panasonic heat pump system with buffer like a volumiser

As conclusion, it is crucial to:

- Properly size the system and piping to ensure nominal flow rate.

- Correctly select the circulation pump with sufficient delivery height (pressure drop) depending on the flow rate

- Carefully design the capacity of the device and start up the system with compensation curve to ensure efficient operation and high comfort level in all temperature conditions